updated April 2024

Summary

- Dipstick and oil filler cap are new & OPERATE DIFFERENT

- The cockpit layout has changed

- The GPS data subscription is maintained and IFR capable

- We had to replace the Tachometer so the tach time is not the current TTAF

See the 8716U page for photos.

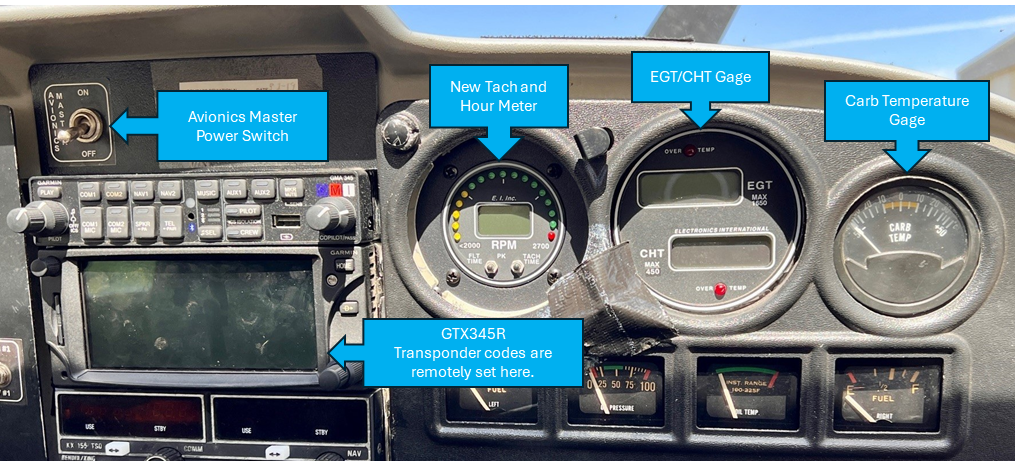

Avionics & Cockpit Changes

- Avionics Master (Power) Switch has been relocated to the top of the avionics stack.

- GMA-345 Com Panel is at the top of the avionics stack. It is the same as, and operates the same as the Comm Panel in the Piper.

- GTN-625 GPS operates the same as the GTN-650 in the Piper but does not contain any radio.

- The transponder is a GTX345R (REMOTE). It is controlled via a touch screen in the GPS. On the lower right side of the GPS display is the transponder control window. It will normally be left in the “1200 ALT” mode unless instructed by ATC to change it. (or you have an emergency or a hijacking.)

- EGT/CHT Gage has been added to the right of the Tach. It measures only one cylinder, that is the #1 cylinder, which is the rear cylinder on the right side. See leaning procedure below.

- Carburetor Temp gage is now functional and is now located to the right of the EGT/CHT gage.

- Hobbs meter has been located lower on the copilot side instrument panel.

Operating Notes

Engine Operation Tips

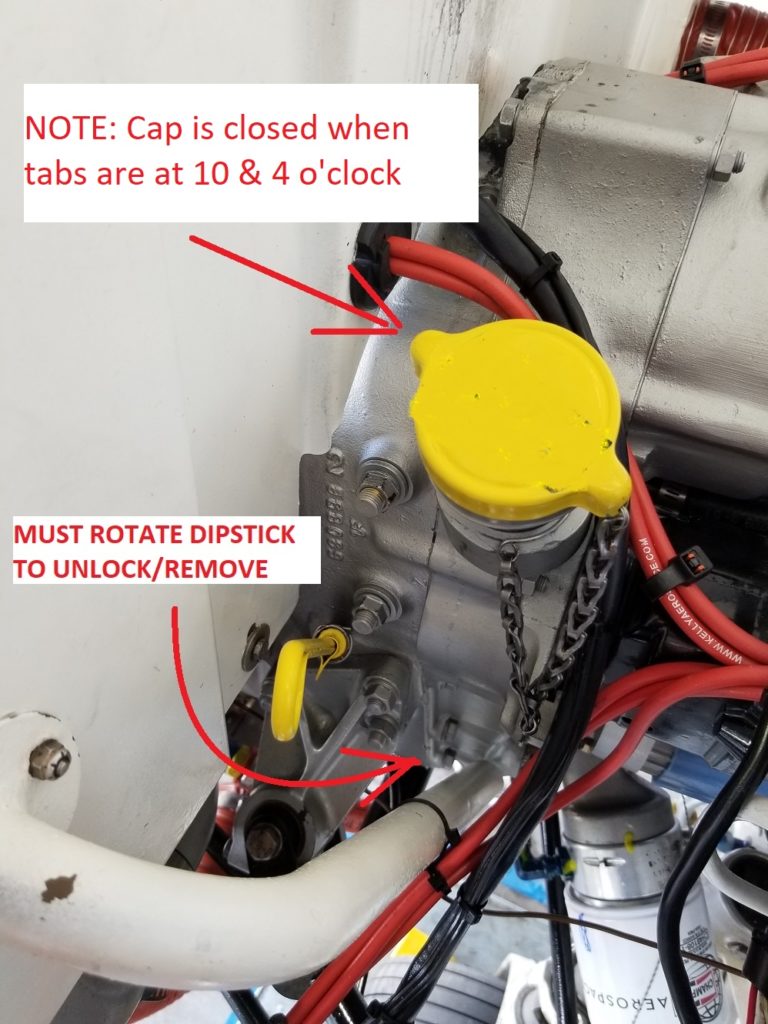

Oil

- Normal oil level at preflight should be no less than 6 quarts. Do not add oil above 6-1/2 quarts. (keep in mind there is about a quart in the external oil cooler too)

- Oil level is measured with the flat side of the dipstick down. This gives a maximum reading. The new engine has a detent for the dipstick that holds/locks it in the ‘flat side down’ position.

- Caution: The dipstick is not removable from this position and MUST be rotated counterclockwise 90 degrees and then pulled out. Re-insert the dipstick with the flat side down to engage the detent and rotate clockwise 90 degrees.

- The Oil filler cap has a new gasket and is harder to turn to the lock position. Be sure you turn it fully clockwise to the stop/lock. Labels are added to guide you. Failure to do so could lead to loss of engine oil.

- In FlightCircle, record the preflight quantity of oil and if there was any oil added. This information is used to monitor engine health when the oil sample is submitted for analysis at each oil change. Omission of this data could lead to incorrect analysis and corrective recommendations after the oil is analyzed.

Engine Temperature

- Avoid shock cooling cylinders with throttle chops and rapid descents. Instead use cruise descent power.

- Avoid high engine Exhaust Gas Temperatures (EGT) and Cylinder Head Temperatures (CHT).

Leaning

- We continue our policy of not leaning below 5K for local/training flights.

- For cross-country cruise, the engine may be leaned no matter what your cruise altitude is.

- Lean to 50 Degrees “rich of peak” EGT.

- If you are not sure about how to lean, ask.

- It is not possible to do “lean of peak” with a 1 channel EGT/CHT.

- EGT temps approaching 1400 degrees (or higher) and CHT of 400 degrees are in the red zone and need to be backed down.

Weight and Balance

- A new weight and balance sheet dated 13 May 2019 is posted in the binder behind the pilot’s seat. Also available on the club website and the aircraft’s file box in the locked cabinet.

Compass

- A new compass correction card is posted on the panel at the top of the avionics stack, below the compass.